New sensor improves burner control and quality

9 October 2019The use of 1MW/unit gas burners in timber production and wood mills can now be improved with the application of the new NIRIS (near infrared intelligent sensor) natural gas sensor from CMR Group, the company claims.

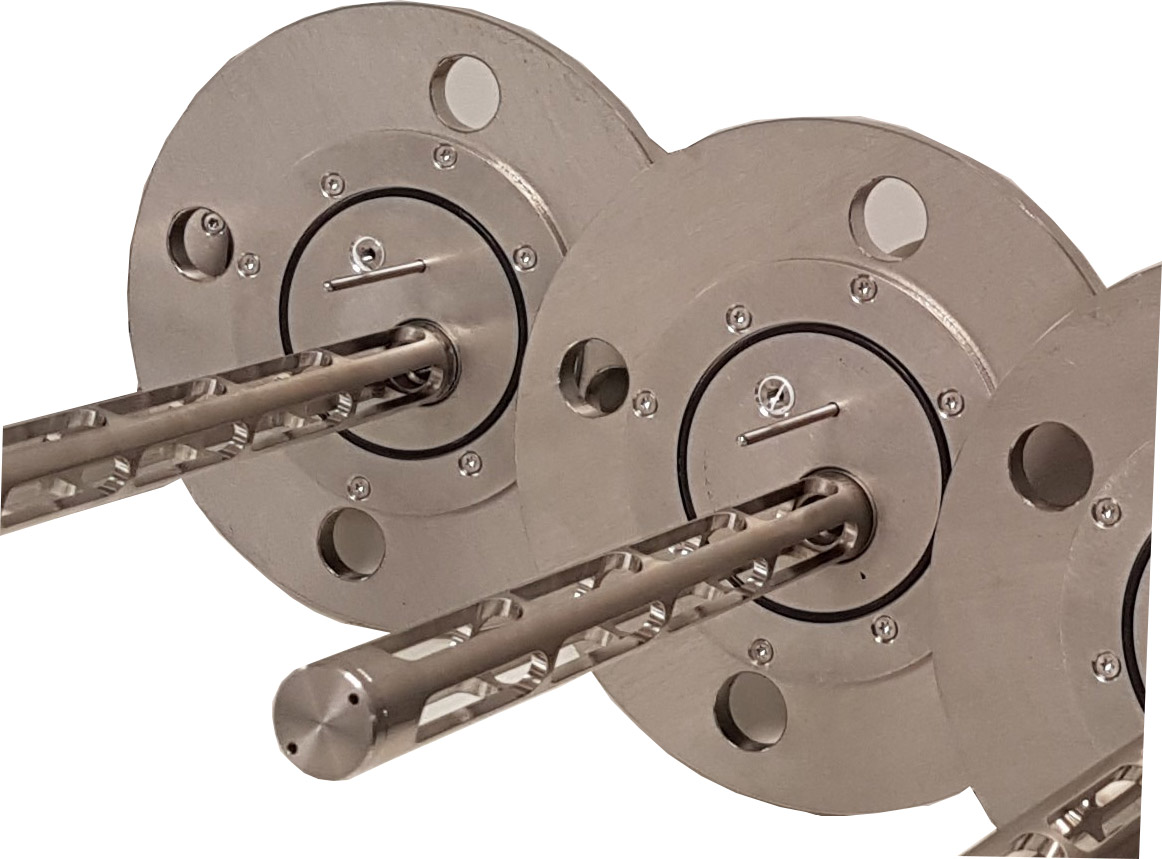

The sensor, which reduces consumption levels of natural gas-powered burners used for heating, furnaces and other industrial purposes through the real time measurement of fuel quality, is directly connected to the gas feeder pipeline, boosting combustion control and providing enhanced quality control and monitoring capabilities.

The sensor is built around smart infrared hardware and data treatment software and features a CAN bus (controller area network) communications facility, which enables the system to be upgradeable without dismantling the sensor for improved performance and retro applications.

Using the sensor to fine tune and calibrate burners can further reduce natural gas consumption levels. Other benefits include lower fuel analysis costs, correct burner performance, stable combustion, and the overall alleviation of time consuming and costly damage to components brought on by inferior or low-grade gas fuels.