Summary

• Demand is hand to mouth.

• Freight rates between the UK and Far East have increased.

• There is a shortage of poplar veneers in China.

• UK imports from China continue to grow.

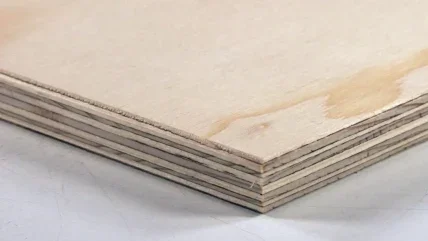

UK consumer demand for most forms of plywood has continued to be largely “hand to mouth”, thus making for a generally unexciting start to 2012. At the same time, plywood margins generally are said to be under mounting pressure, with a leading distributor commenting: “This market is so fragile at the moment that people are reluctant to pass on price increases.”

As for the Chinese plywood arriving in the UK, several contacts believe that the material “may prove difficult to shift”, and one added that “the hope must be that, having scaled back their orders in December, people may need to restock”. Indeed, one lone, but experienced, voice predicted this week that shortages could emerge before the end of the first quarter due to currency, holiday and freight factors.

FOB prices in China have remained fairly stable but for journeys between the Far East and the UK shipping lines have imposed early-year freight rate increases of, reportedly, between US$50-200 per 40ft container. However, one Chinese specialist said: “With the reduced volume of cargo after the holidays, it is likely that rates will fall again.”

Chinese product

Within China itself, suppliers of red-faced poplar plywood are experiencing a shortfall in poplar veneer due to the impact of sub-zero temperatures on logging and difficulty in air-drying the veneers. “A number of mills are closed for extended holidays while the shortage persists,” TTJ was told.

And the country’s mills are also likely to experience labour shortages following Chinese New Year. Traditionally, a significant number of workers fail to return after this holiday period, resulting in mills being unable to work to full capacity. “Any new workers are inexperienced and unfamiliar with plywood production and quality requirements,” a regional expert said. “As a consequence, shipments are delayed and serious quality issues can arise.”

Latest figures from The Timber Trade Federation (TTF) confirmed China’s growing dominance of UK hardwood plywood imports. In the first 10 months of last year the country had a 49% share of the UK market, compared to 42% in January-October 2010. With total UK imports rising 7% to 770,000m³ over the same comparative periods, this means Chinese exports to the UK jumped 23% year on year.

Malaysia’s slice of UK hardwood plywood imports remains in constant decline, falling from 19% in the first 10 months of 2010 to just 13% in the same period last year.

The purchasing activities of regular UK customers has been relatively quiet so far this year; however, producers in Malaysia are understood to have enjoyed richer export pickings in other Asian countries, the Middle East and, for certain grades, in the US.

FOB prices for Malaysian plywood have reportedly been raised by typically US$10 per m³ for March shipment as a reflection of the impact of the rainy season on log supply. “Importers who have not got plywood on the water at the moment could have a problem,” said one contact. “Prices have the potential to go significantly higher.”

South American plywood

As for the prospects for Brazilian hardwood plywood shipments to the UK market, this continues to be what one contact described this week as “basically a non-starter”. He added: “Even if the Brazilians were competitive on price, most buyers would be looking first at Chinese or Malaysian material.”

Staying in South America, the fire that devastated Arauco’s major Nueva Aldea mill in Chile has had an almost immediate effect on the softwood plywood market. Elliottii pine plywood producers in Brazil have responded by hiking FOB prices by between 10-20%, prompting many experts to wonder whether anyone in the UK will be tempted to buy at these elevated levels. “It won’t help the Brazilians to sell more – I reckon most people will go for Chinese material,” said one.

The Brazilian mills are understood to have already sold out for February and for the first half of March. “There is no inventory available in Brazil itself; the mills there had not been running at full capacity,” said a regional specialist. “So it depends to what extent mills have the scope to increase their output.” Some mills that do not traditionally engage in export business might be tempted to enter the market under current circumstances, he added.

Other producers in Chile itself and elsewhere in South America have experienced an upturn in enquiries as large importers around the world look to find a replacement for the lost Arauco supply. “Agents with stock on the ground will have done pretty well,” said a UK distributor.

Statistics

Compared to the UK, the near Continent is widely regarded as traditionally a more energetic buyer of Chilean plywood – particularly the Benelux countries. However, latest TTF figures confirm that the South American country accounted for a sizeable 11% slice of the 373,000m³ of softwood plywood imported into the UK in the first 10 months of last year. Brazil commanded a 38% share compared to 45% in the January-October 2010 period; meanwhile, the proportion from China jumped from 13% to 21%, helped by a “surge” last summer when its sales into the UK averaged 11,000m³ per month, according to the TTF.

If availability of Chilean ply on mainland Europe becomes tight, some believe consumers could switch to spruce ply from Finland. Producers there are already warning that a knock-on effect of events at Arauco could be higher Finnish spruce ply prices for the second quarter. At the moment, first-quarter values have been held at fourth-quarter 2011 levels.

Finnish trade

In December, UK demand for Finnish plywood did no more than tick along at low levels as customers looked to keep their end-year stocks to a minimum. In the early weeks of 2012, Finland’s spruce plywood sales into this country have been steady at expected levels. A “steady” start to the year was also reported for volumes of Finnish birch plywood moving to the UK, with orders booked until the end of February. Prices are stable and one contact said he “wouldn’t be surprised if they stayed where they were until the middle of the year at least, depending on how demand fares”.

Recent gains by the pound in relation to the euro are said to have alleviated the pressure for price increases on plywood heading from the Baltics to the UK, demand for which in this country is said to have started 2012 “steadily across the board”. “We are well booked into March,” said a regional specialist. The last vestiges of demand for projects relating to the London Olympics are continuing to take up the slack there might otherwise have been in the market, he added.

During this winter, shipments from the Baltics have been unaffected – to date, at least – by the sea ice and deep forest snow that disrupted supply in the previous two years.