Ligna reflects recovery

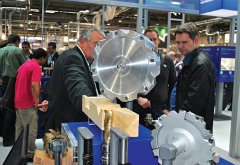

1 June 2013Visitors and exhibitors seemed to come away from this year’s Ligna exhibition happy, confident that the international timber technology market, and by definition, the international timber processing and using markets were firmly on the road to recovery.

The show was two halls smaller than the last event two years ago, but this was largely, say organisers, in response to exhibitors' demand for more compact display space, rather than a decline in stand numbers. There was still a total of 1,637 exhibitors from 46 countries.

Visitor numbers were also strong, at 90,000. That was around the same as 2011, but an upturn on the low of 2009 when manufacturers reported global wood technology sales down by up to 60%.

The show seemed to bear out reports that the US market is on the up, with housing starts finally starting to lift after years of decline and stagnation. The organisers reported North American visitors up 52%.

At the time of going to press there was no breakout of figures for visitors from the UK and Ireland. But the anecdotal evidence was that numbers were at least as good as 2011, and several exhibitors reported a strong showing.

New manufacturer Lohmeyer, which has its German-designed machines made in China, said that it had not planned to enter the UK market yet, but that the number of approaches from potential UK agents and customers was making it think again.

Several companies also reported an upturn in UK enquiries and sales. Weinig UK managing director Malcolm Cuthbertson reported a "very strong start to the year".

"2012 was better than 2011, and it looks like 2013 is going to be better still," he said.

Combilift was also bullish about the UK and Irish markets, and its business overall. The company is on line for record production of 3,000 units this year and has had to open up its old factory to cope. And it took at least one order on its stand each day of Ligna. Söderhamn has edge

Swedish sawmill machinery manufacturer Söderhamn Eriksson showed Ligna visitors how they could get more value out of boards using new intelligent scanning technology.

A Catech high-speed edging line with new scanning system, developed in-house by Söderhamn Eriksson, took pride of place on the stand. The 450m/min machine on display had already been sold to a company in Norway.

The scanning frame can be equipped with linear cameras for grade detection of the upper side of the board to allow full value optimisation. It is designed to eke out the best value in the quality of the timber being processed, not simply the yield.

"This is what we are focusing on more and more with our customers," said Darren Oldham, managing director of Söderhamn Eriksson Ltd.

"Companies are looking to make improvements without committing to spend £2m, so a lot of what we make is designed for retrofit. We have done a lot of edger upgrades in the UK during the last three years."

Stenner picks up orders

Ligna stalwart Stenner UK enjoyed a fruitful appearance at Hannover this year, registering orders from across the world for its resaws.

It also secured business for partners Paul GmbH (edgers and cross-cut saws) and Primultini (high-speed bandmill systems), both of which Stenner represents in the UK.

Stenner resaw orders were from Australia, Israel, Dubai and France, while orders for Paul and Primultini came from England and Scotland.

"Not only have we taken significant orders for our own equipment during the show but we have secured business to a total volume of almost £800,000 for our partners," said Stenner sales director Fred Harding.

"We also have strong enquiries from Ireland, the Middle East and the Far East, which we expect to turn into confirmed orders within the next two to three weeks."

On its stand Stenner displayed its redesigned MHS9 horizontal resaw, featuring a new overhead feed system and also highlighted its recently developed bandsaw spray lubrication system.

Vollmer takes pulse

There was no mistaking the highlight of German grinding and eroding technology specialist Vollmer's stand this year.

The QXD 250 eroding machine had its own orange carpet to mirror the style of Vollmer's Technology and Services Centre in Biberach. At the heart of the QXD 250 is Vollmer's Vpulse EDM, which can increase the speed of tool production or increase tool surface quality by using individually cycled eroding impulses.

The results, says Vollmer, lead to a 30% increase in the speed of PCD tool production and at least a two-fold improvement in tool surface quality compared with standard eroding technology.

The company says the QXD 250 effectively makes PCD tool production cheaper and allows PCD tool manufacturers to react in a targeted way to the demands of their customers and markets.

Peter Allen, managing director of Vollmer UK, reported a good turnout from the UK and Ireland, with several of the large Irish sawmillers in attendance.

Electric atmosphere at Springer

The world premiere of the first electrically-driven, beltless trimmer is the news at Springer.

Out go the belts and hydraulics and in comes electrical control of a swinging saw arm which, Springer says, gives a perfect sawing movement and means temperature effects, actuation times and efficiency issues are no longer a problem.

The E-Cut 200's power comes from two centralised, externallypositioned motors. In fact, all drive components are on the outside of the unit, with the inside working zone sealed to prevent damage to components.

A compact dust-shielding case has been designed for retrofit into existing saw lines.

Springer CEO Gero Springer said the E-Cut 200, which cuts board of 2.4-6m length, had already been run at an Austrian customer for more than 1,000 hours.

The E-Cut 200 has 120-200 cutting cycles per minute and cuts wood thickness of 100mm and widths of up to 225mm.