The Plywood Saga… Continued

24 October 2019John Park continues his series of articles looking at the problem of misleading descriptions of plywood

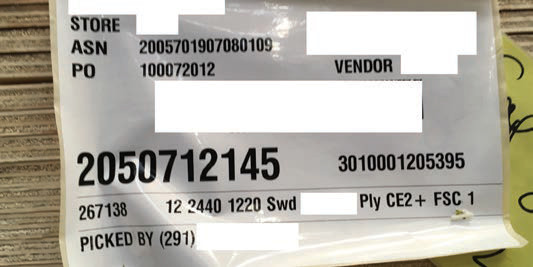

So, I googled ‘CE2+ plywood’ and there it is, with inaccurate pop-down description to boot, being widely perpetuated by the trade! But whilst WBP plywood – which is still being described as extant together with a number of incorrect expansions of WBP – is a relic from the past, ‘CE2+ plywood’ is just downright wrong!

We tried to get that point across to the trade at a TTF meeting, as indeed did Michael Harrod in his letter to the TTJ in 2009, but to no avail. Once the incessant trickle bursts the dam, it is easier to go with the flow, which is what the plywood trade did with CE2+ and interestingly CE2+ is now far more prevalent than ‘WBP’.

And what has also been highlighted in the recent TTF plywood report is the ignorance within the plywood trade of obligations under the Construction Products Regulation (CPR) – if you haven’t done so already, find it at ec.europa.eu, by googling ‘construction products regulation’.

Construction Products Regulation, Article 13.2 extract: “Before placing a construction product on the market, importers shall ensure that the assessment and the verification of constancy of performance has been carried out by the manufacturer. … They shall also ensure that the product, where required, bears the CE marking, that the product is accompanied by the required documents and that the manufacturer has complied with the requirements set out in Article 11(4) and (5).”

The CPR places legal obligations on both importers and distributors; it is not just something to read when you have the time. And any company importing products such as plywood should also be in possession of and be familiar with the harmonised standard (hEN) and pertinent product standards to be at least on a par with, or better still one step ahead of, manufacturers. If you don’t know what they should be doing, how can you be sure that that is what they are actually doing?

There is, unfortunately, one other document difficulty facing wood-based panels generally for the time being and that is that hEN 13986:2004+A1:2015, written under the Construction Products Directive, is not CPR-compliant but it has to be used as if it were. From one practicalities aspect, all information in Annex ZA.2.2 Declaration of Performance (DoP) and Annex ZA.3 (CE marking and labelling), should be disregarded, being replaced by “Regulation (EU) No 305/2011 (ie the CPR) as amended contains provisions for the DoP and the CE marking”.

And all the time the number one priority of business is to make a profit there will always be construction companies prepared to track down an “equivalent” cheaper product which, whilst not exactly meeting the building designer’s specification, should “do the job”. That soffit, pictured in last month’s Talking Timber column, perhaps?

One intention behind the DoP and the CE marking is in order to avoid such occurrences but when there is a failure it facilitates traceability along the supply chain and back to the manufacturer. Because, as supplier, you surely wouldn’t want to be held accountable, would you? If the manufacturer is anonymous, does the importer or the distributor become liable?

The plywood fail-safe mechanism, of course, is to cut a few samples from one or two boards and pop them into a bucket of cold water overnight – over lunchtime would suffice in some cases – by morning it will be clearly evident; in the worst cases you will have a bucket of veneers. It doesn’t address biological durability but it does satisfy one of the requirements of CPR Article 13.

CPR Article 13.2, (14.2 for distributors) paragraph two, also states: “Furthermore, where the product presents a risk, the importer shall inform the manufacturer and the market surveillance authorities thereof”. Should there ever be a need for it to become ‘official’, it might also become very, very costly!