Next generation wises up

5 October 2013The next generation of Frame Wise’s Wise Wall closed panel timber frame system has just been launched – and there will be more to come. Robin Meade reports

Frame Wise, winner of the TTJ Timber Innovation Award , has made no attempt to patent its Wise Wall T closed panel timber frame system. The innovation is not in the individual elements of the system, the company said, but how these components are assembled.

"Patents and Intellectual Property is a very lengthy process and, quite frankly, our industry is moving and changing so quickly, you need to be looking ahead at the next thing, not behind you," said Frame Wise managing director Simon Orrells. In fact, before celebrations had ended, the next-generation Wise Wall L was being launched at Timber Expo, where the company's panel system was featured at the Fabric First theatre.

Wise Wall now accounts for 40% of the company's output even though it remains a premium product, and it continues to gain traction, especially with self-build enthusiasts and larger projects, particularly schools.

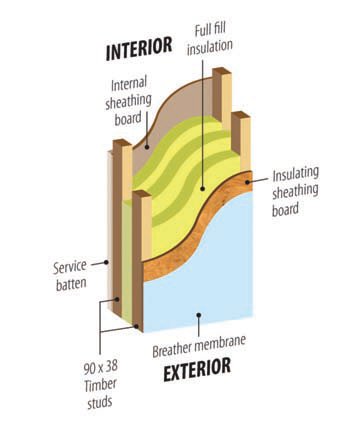

Wise Wall is manufactured at the company's five-acre site in Presteigne, Powys, where two 90mm panels are brought together with a 90mm separation, fully filled with glass mineral wool insulation to create an airtight structure which breathes, through the use of open fibre insulation and specialist breather membranes.

The process achieves greater airtightness, enhanced U-values ranging from 0.11-0.14W/m²K using a standard 270mm-wide panel and improved thermal bridging. The T series, or twin, is big brother to the first single panel system. Wise Wall T has a high BREEAM rating and surpasses the latest Code for Sustainable Homes levels to achieve Passivhaus standards and provides a full Fabric First solution. It has BM TRADA Q Mark, ISO 9001 and ISO 14001 accreditation. The insulation is made by independent UK company Superglass Insulation, which supplies its Timber & Rafter Batt 35 medium density mineral wool roll, designed for thermal, acoustic insulation and fire resistance.

"Wise Wall was our move away from the timber frame panel system and to improve the insulation value," said Mr Orrells. "We were trying to do more offsite, bring a cost reduction and create better values. At the time you brought all the components to the site, but the condition in which they arrived, how they were stored and how they went up was such that one of the things you could not do was to guarantee performance. Once it was up that performance gap could be huge. If we could do this offsite we felt we could add value as well.

"It is a premium product, yes; where you are typically looking at 6-8% of the contract value, this is 22%. But then you have to look at what you are taking away in the operations onsite. There is an awful lot of overlap and that costs money, and you also have the advantages of speed, maintaining quality and performance. Our USP is delivering better value."

One of the unique selling points was providing a breathable wall and that has been a particular attraction to the self-build and schools sector. "A lot of people can't understand how something can be airtight and breathable, but breathability is one of the biggest drivers because it gives such a better environment inside and negates condensation build-up," said Mr Orrells.

"With the reduction in budgets and rising costs, energy efficiency is a major consideration for the public sector," he continued. "Social housing providers are trying to address the rise in fuel poverty and in the self-build housing sector whole life costs are a major consideration. We are using fully recyclable glass fibre and we can use any natural product."

In its submission for the TTJ Awards the company cited a traditional-style six-bedroom home with a specification that it did not rely on any heating or cooling systems. The 310m² space took three weeks to make weathertight from delivery and cost just under £50,000 for the timber frame element. The building achieved a U-value of 0.11W/m²K and Code for Sustainable Homes level 5. It was also the first timber frame construction to have a full Technology Strategy Board Building Performance Evaluation.

The company also cited the Earth Sciences centre at the Shrewsbury Sixth Form College. Here, the structural timber frame was erected in three weeks, under pressure to meet the start of the academic year, and came in under budget at £125,000, with a U-value of 0.12W/m²K.

Mr Orrells is the longest serving member of the UK Timber Frame Association (UKTFA), now the Structural Timber Association, and was chairman for two years.

His company is a family business that began as a timber frame erector in 1997, moving to manufacturing in 2002. It has three production lines and employs 38 people, with additional teams on site, and has been growing fast in the past few years.

"We provide hybrid solutions, our buildings are bespoke; we have not tried to compete panel for panel or margin for margin. We might use three, four, five different timber solutions in one project. Each is unique," said Mr Orrells.